In the walk-in , there was no floor, only a sub-floor. The walk-in connects the bathroom and the master bedroom and, in the spirit of the former owner, the walk-in floor would be made of the same porcelain as the bathroom. I liked the idea because it would unify and enlarge the space. Only problem, the former owner had not bought enough porcelain tiles to make the complete surface.

Finding an old porcelain, easy?

But my idea was made, I wanted this same porcelain. This is how my father and I went over and over to hardware stores and supermarkets to find THE porcelain. I wasn’t asking for a lot: 12 inches by 12 inches, in an off-white, solid, and matte color.

Phew! This is how I discovered that I was very naive and that it was impossible to find an identical porcelain. It was at the Canac Marquis that I found what came closest to it. The only difference? This is ceramic (not porcelain) 1mm larger and having a few shiny lines. Too bad, we want to recover and work as well as possible with what there is currently and with our financial means. We take her !

Laying ceramics

This is how yesterday we made our first ceramic. We had already read on the subject and seen shows on TV, it shouldn’t be that complicated. I envisioned this as a small 2 hour project. Again, what beautiful naivety! 🙂

It took us almost 4 hours. The steps, in order:

- First, we went to solidify the floor from below.

- Then screws were added to the sub-floor, again to solidify.

- Then, we mixed the mortar for a ration of 2.5 powder for 1 water (We did not have the right tool to stir, we managed as best we can and that ended up being mixed up with the hands. What giggles!)

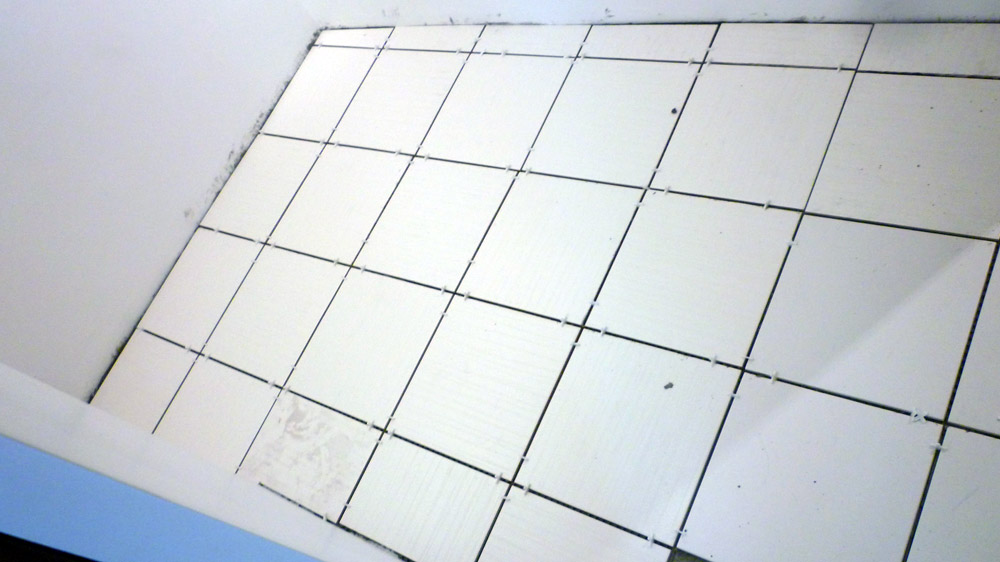

- Finally, we applied the mortar, gradually and in places, in order to lay the ceramics there while making sure to install them two braces per edge.

Some pictures

We cut our tiles as we went along, only to realize that the back wall was really crooked! Once again, you have to work with what you have.

We are happy with the final result.

We let dry 48 hours, before finalizing with the last angle cuts, since we do not have the right tool. Our manual saw only makes straight and diagonal cuts.

Leave a Reply